Last week, I said I was going to post about a new project I’ve been working on, or there would be another tractor maintenance post. Â We got the tail end of Tropical Storm Nicole on Thursday and Friday, and the storm won. Â More on that soon.

If you end up with a front end loader at some point, you will get more life out of it with the following tips:

1. Â Buy, read, and understand the manual for your loader. Â If you purchased your tractor new or from a solid source, you probably already have one. Â If not, there are several sources available online. Â Follow that manual, it will tell you about the required regular maintenance.

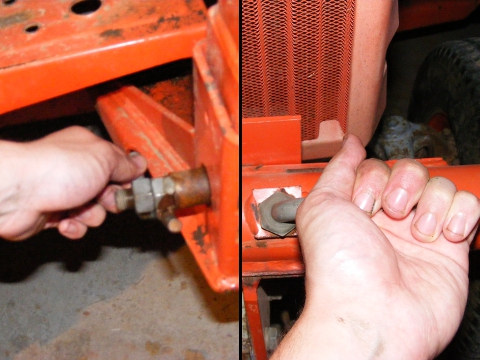

2. Â Check to make sure the attachment points are locked down. Â I have to hand tighten a wedge nut and lock nut on either side of the load frame, and two more on the front of the tractor. Â I check these out of habit before I take the tractor out and use it.

3. Â Check the bucket for damage. Â The corners of this bucket need some serious repair, and the bucket is looking pretty tired overall. Â I’ll have to do something about that.

4.  Every 10 hours, grease every zerk/fitting/nipple on the loader.  Make sure to clean the old grease off the zerk first, and leave a dab of fresh grease on it when you’re done.  Use the type of grease specified in your manual.  Pump the grease in until you see fresh grease coming out of the joint like in this picture.

Both ends of a hydraulic cylinder should have a zerk. Â Every pivot in the loader should have a zerk as well. Â You might have to lift the tractor to get access or even see all of them. Â If a zerk snaps off don’t panic, but make sure to replace it ASAP. Â Bigger fancier (newer) tractors might have centralized greasing systems, but mine doesn’t. Â For now.

Make sure to check out the gallery and links for more detailed pictures! Â See you next time!

- We meet again…

- L: Wedge pin with lock nut. R: Front attachment.

- Dirty and hard to access, but you have to find a way!

- Nice view!

- Clean and ready for grease!

- I couldn’t find an orange grease gun to match.

- Fresh grease squeezing out of the joint

- Pressurized hydraulic fluid WILL mess you up.

- about 600 hours of use takes its toll on a front loader.

- I totally didn’t do this!